|

Huntsville AL (SPX) Apr 13, 2010 On Tuesday, March 30, NASA and their industry partners unveiled a revolutionary new manufacturing process that could lower the cost of producing a tank dome - the end piece of a fuel tank - as much as 25 percent by using commercial materials and state-of-the-art technologies in an innovative application. Manufacturing a traditional tank dome requires welding eight curved, pie-shaped pieces of metal together, and a fitting on the top and bottom. This requires several costly manufacturing and inspection steps to ensure the welds are acceptable for flight. The new application calls for one weld to join two large flat blank panels together, eliminating at least seven major welds, reducing steps and cost. This is the first time this combination of technologies and alloy has been successfully applied to produce a full-scale 18-foot-diameter, 2195-aluminum-lithium dome that is lighter, has fewer defects and cost less to develop. The process employs friction stir welding, a solid state joining process; spin forming, a metal working process used to form symmetric parts; and 2195 aluminum lithium, a higher-strength, lower-density alloy, and could be used in the design of launch vehicles, crew vehicles, habitat modules, and other space hardware. One additional full-scale development tank dome is scheduled for manufacture and testing in the coming months as part of the joint, four-year technology demonstration program. NASA's Marshall Space Flight Center and Langley Research Center in Hampton, Va., partnered with Lockheed Martin Space Systems in Denver, Colo., and MT Aerospace in Augsburg, Germany, to push the envelope in dome manufacturing by making use of existing commercial materials and cutting edge technology. This international partnership demonstrates the agency's desire to tap into rich sources of innovation to help address technical challenges that will mutually benefit NASA and next-generation space exploration.

Share This Article With Planet Earth

Related Links - Space Technology News - Applications and Research

Getting The Wrinkles Out Transparent Film Development

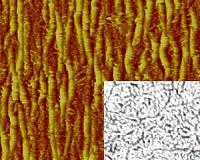

Getting The Wrinkles Out Transparent Film DevelopmentWashington DC (SPX) Apr 06, 2010 A closer look at a promising nanotube coating that might one day improve solar cells has turned up a few unexpected wrinkles, according to new research* conducted at the National Institute of Standards and Technology (NIST) and North Dakota State University (NDSU)-research that also may help scientists iron out a solution. The scientists have found that coatings made of single-walled carbo ... read more |

|

| The content herein, unless otherwise known to be public domain, are Copyright 1995-2010 - SpaceDaily. AFP and UPI Wire Stories are copyright Agence France-Presse and United Press International. ESA Portal Reports are copyright European Space Agency. All NASA sourced material is public domain. Additional copyrights may apply in whole or part to other bona fide parties. Advertising does not imply endorsement,agreement or approval of any opinions, statements or information provided by SpaceDaily on any Web page published or hosted by SpaceDaily. Privacy Statement |